UNO incorporates our own ideas generously to develop the system that is suitable for the customer's needs.

UNO has valued "Originality" in manufacturing systems since we invented the "UNO Patented automatic ruled line printing machine" back in the 1950's. Since then, UNO has developed the fully automated book printing & binding systems for Textbooks, Comic books, etc. and the fully automated notebook manufacturing system by In-house development and In-house manufacturing. Our fully automated manufacturing systems are not simply a combination of several independent machines but we create them with our proven technology and characteristic ideas. Therefore, they are second to none systems and bring more and an up-graded happiness to our clients. We are currently focusing on "Notebook manufacturing system", "File manufacturing system" and "UNO newly developed system" for the commercial printing market.

Excellent system for multi-product, small lot sized production!

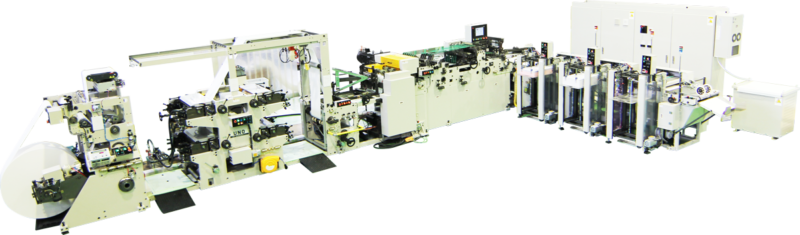

Notebook manufacturing system

UNO's system can minimise the Changeover time! UNO's fully automatic flexo printing and note manufacturing system can manufacture high quality notebooks thanks to the new servo technology. Our design focuses on reducing the Changeover time as much as possible so the customer who is planning "multi-product, small lot sized production" will appreciate this system. This system is not only printing but also gluing & sewing.

The system that makes file & binder manufacturing short & simple!

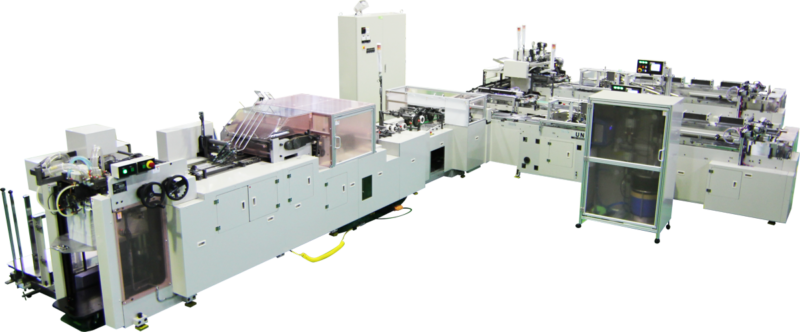

File manufacturing system

"UNO's bookbinding automation know-how matches your original specifications and special files such as Clear file". The File manufacturing system feeds the pasteboards and then inserts the customer's original binding parts. After these materials are turned to files, then the system collect them (10 files) and pack them. There is also a system for the special files such as Clear file.

A system developed by UNO's experiences and the latest technologies!

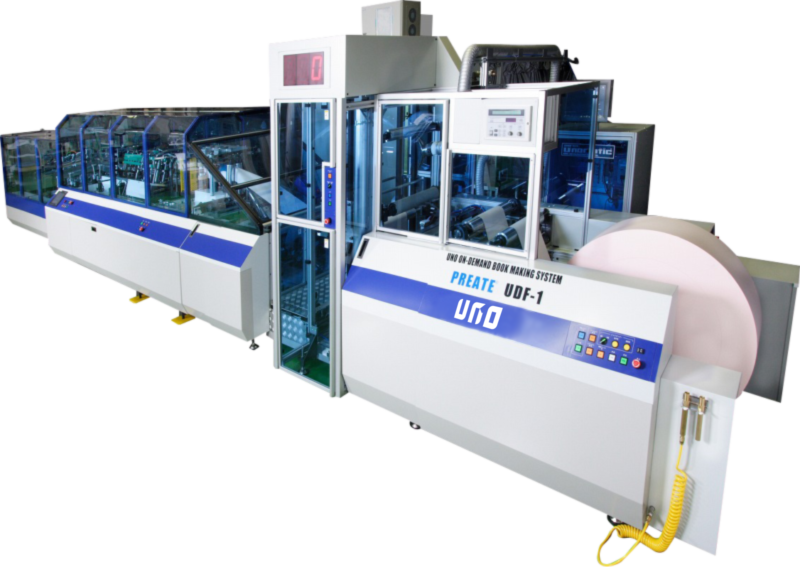

UNO newly-developed system

As a leading In-line Technical Group of printing and book binding, we are offering the state of the art system which is able to produce "the finest product quality saddle stitching book" by variable bookbinding from the Digital Printing Roll. This print on demand book manufacturing system is called "PREATE UDF-1". This system starts with folding the roll paper, cutting, saddle stitching and binding (glue or wire), and even the number of folded sheets is different for each book by variable printing, the nails come out and sorted out by each book and send it to the binding process thanks to the special mechanism. By this way, the system can achieve the high speed variable binding with a roll speed of 200m / min and 8-100 pages.