UNO Passport production solution is loved worldwide!

UNO Passport production solution is completed by these three machines "Lead Machine", "Follow Machine" and "Laser Perforation System" for a three stage process. However the solution can be achieved by more integrated machines (one or two machines) or more individual machines (four or more machines). It is also possible to purchase our "Laser Perforation System" only, if you are using other manufacturer's systems in the previous process.

3 Types of UNO Passport production solution

Just set the materials, UNO machine will do the rest!

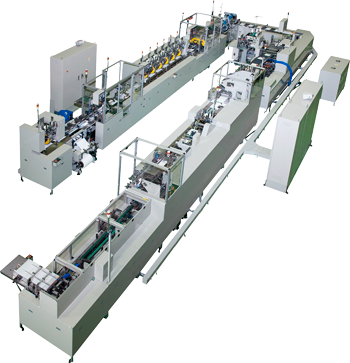

Lead Machine

The Lead Machine collates the sheets, sews those sheets by the dedicated sewing machines, and attaches the cover & those sewn sheets. In this process, the system can also take RFID inlay cards (e-Cards), RFID inlay sheets (to make e-Covers) or e-Covers for e-Passport production. Materials such as paper, cover, thread, and inlay at the entrance will be turned to the strip (2-up booklets) at the exit.

Die cutting with speed and quality!

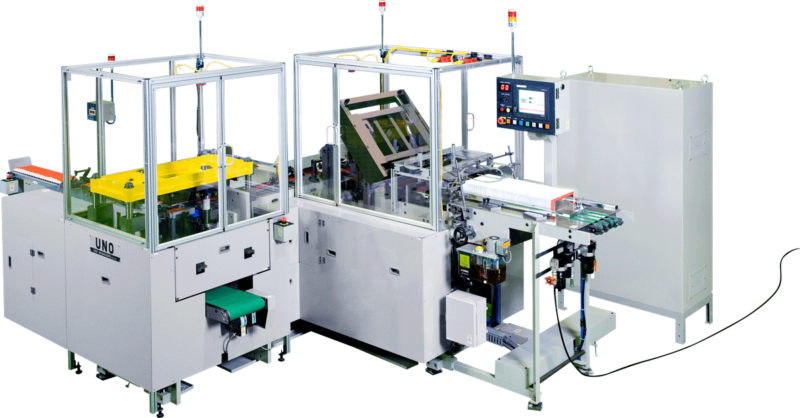

Follow Machine

After the Lead Machine, the strip will be fed to this Follow Machine and come out as passport size booklets by die cutting. This system can be used as a stand alone or linked with the laser perforation system (which will be the next process of passport manufacuturing).

High speed and stable numbering and laser perforating system!

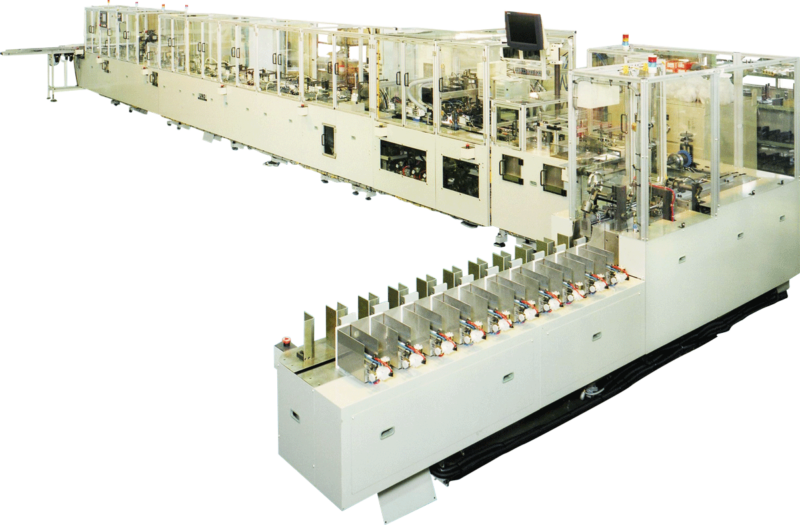

Laser Perforation

After the Follow Machine, the strip becomes the passport size booklet. This system prints the passport number (numbering) and laser perforating with meeting your specific requirements. As the demand of the high security features is increasing, we are integrating a lot of special devices such as Laser marking, labeling and packaging with this system these days. Despite the increased number of special devices, UNO's advanced material handling technology and centralized control integrates with multiple special devices seamlessly.